- Press. Eliminate gaps and air bubbles by running your fingers over the butyl tape, pressing it down and around all of the surface’s bumps and curves to ensure every bit of the tape is stuck down.

- Installing floor marking tape is a straightforward process that typically involves cleaning the area where the tape will be applied and then applying the tape using a roller or squeegee. Once in place, the tape should be allowed to fully adhere to the surface before walking on it or using heavy machinery over it.

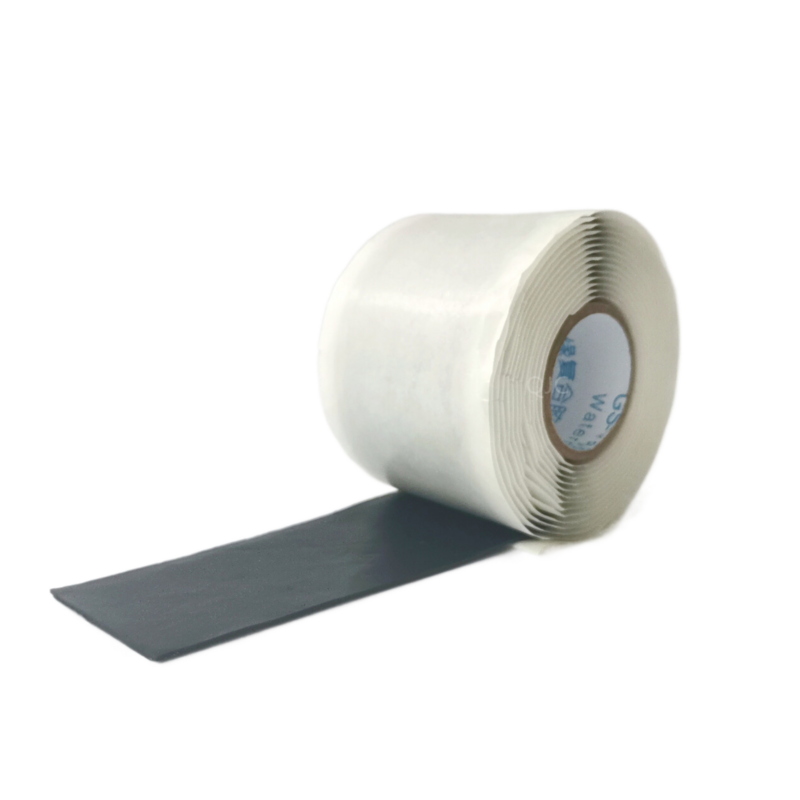

Self-fusing silicone electrical tape finds applications across various industries. In electrical installations, it is commonly used for insulating splices, protecting wiring, and securing cables in both residential and commercial projects. Its resistance to heat makes it an ideal choice for high-performance applications, such as in automotive and aerospace sectors.

These are heavy-duty control boxes engineered with sophistication to meet the complex demands of industrial systems. They are primarily used to automate heavy machinery in industrial applications such as manufacturing and waste management. Industrial control boxes feature additional components such as cooling units, which equip them to withstand harsh conditions.

Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues

Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues 23 rubber splicing tape. However, advancements in recycling technologies and the development of more eco-friendly rubber compounds are mitigating these concerns. Moreover, the energy efficiency gained from using such tapes in insulation often offsets their production environmental impact.

23 rubber splicing tape. However, advancements in recycling technologies and the development of more eco-friendly rubber compounds are mitigating these concerns. Moreover, the energy efficiency gained from using such tapes in insulation often offsets their production environmental impact.ELITE TAPE IS YOUR TRUSTED SOURCE FOR SINGLE COATED TAPES

Engineered to beat the heat.

1. Warehouses In a bustling warehouse, where machinery, personnel, and products interact, clear pathways are essential. Red and white tape can demarcate pedestrian walkways, separate moving zones, or highlight dangerous areas, such as near forklifts.

- Home Improvement and DIY Projects For general repairs, home electrical systems, and protecting outdoor wiring.

(1) The thermal stability is 180 ℃. At this temperature, the product can be used safely for more than 10 years, saving many after-sales troubles;

self amalgamating rubber. The simplicity of use – applying the product and letting it cure in the presence of air – makes home repairs accessible and convenient for everyone.

self amalgamating rubber. The simplicity of use – applying the product and letting it cure in the presence of air – makes home repairs accessible and convenient for everyone.In the industrial landscape, control boxes are the linchpins of efficiency and safety. Here’s how:

The primary tapes used in electrical applications are vinyl, rubber, mastic, and varnished cambric. These products have been used in electrical work for many years, are code approved, and conform to key industry standards, including UL 520, ASTM D1000, and CSA 22.2. The Table below lists the primary uses for each of these types of tape.

When designing a control box, you should not take it lightly irrespective of the simplicity of the box you intend to build. Here are three factors that will help you design a functional, reliable, and safe control box.

insulation tape.

Rubber tapes repel moisture and are a great solution for outdoor applications or in manholes where water may occasionally seep in.